Businesses & Products

Precision Polishing Pad Business

Creating fine chemical materials that will continue to brighten our lives into the future.

The increasing precision of electronic and precision equipment that has accompanied advances in computers, communications, and networking has led to major changes in our lifestyles. High-precision polishing is an essential process in the manufacture of the materials—silicon wafers and other semiconductor materials, hard disk substrates, liquid crystal glass—that will be used in many of the high-tech equipment developed now and in the future.

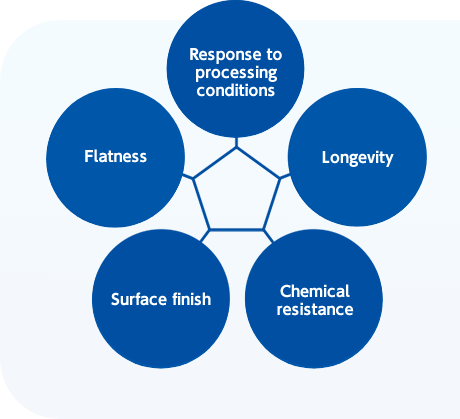

Our “Bellatrix” high-precision polishing pads are used to provide final finishing in important processes at production sites that require high performance, stable quality, and the satisfaction of strict polishing conditions. The Bellatrix brand is highly trusted in an industry known for rapid technological innovations.

Bellatrix®High-Precision Polishing Pads

A polishing pad developed for high-precision polishing of materials such as silicon wafers and other semiconductor materials, metals, and glass.

With our extensive lineup of product types tailored to a variety of processing conditions, we can provide the surface finish that you require.

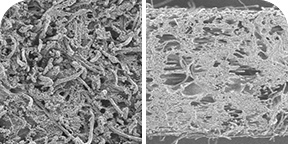

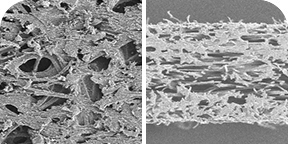

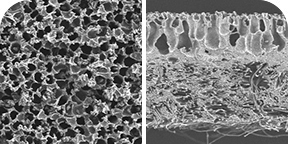

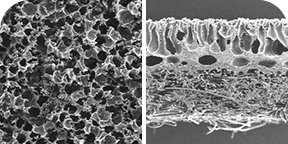

Non-woven Type

A primary polishing pad made of polyurethane bonded to a non-woven fabric made of special polyester fibers.

Provides excellent polishing accuracy and longevity.

KE013

A soft non-woven type polishing pad. Ideal for low-pressure processing conditions, this pad provides an excellent surface finish and is also suitable for edge mirror finishing.

K0013

A specially hardened polishing pad on medium-hard non-woven fabric. Ideal for medium-pressure processing conditions. This is a standard product with a high removal rate, long life, and excellent flatness, making it suitable for use as a primary polishing pad in a wide range of applications.

N0571

A specially hardened polishing pad on hard non-woven fabric. Ideal for medium- to high-pressure processing conditions. Developed for primary polishing, this pad provides excellent flatness, surface finish, and longevity.

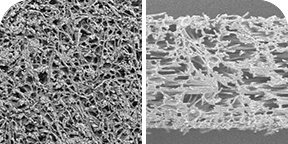

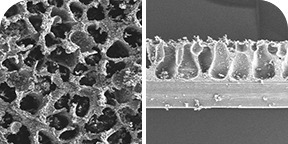

Suede Type

A pad for final polishing on which a nap layer is formed on the polyurethane-impregnated non-woven fabric or PET sheet. Provides the best surface finish in applications requiring high-precision finishing.

N7512

The formation of a soft nap layer on a soft base coupled with a fine-particle slurry creates an excellent surface finish.

K0034

A polishing pad with a medium-hard nap layer formed on a medium-hard base, making it ideal for low- to medium-pressure processing conditions. It has excellent chemical resistance and is a highly versatile standard product for final polishing.

NP515

A polishing pad with a hard nap layer formed on a PET base. Enables highly precise polishing with an excellent removal rate and low waviness and roll-off.

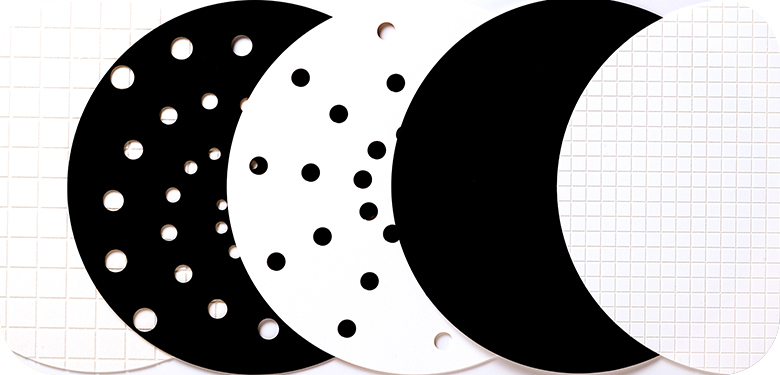

Secondary Processing ServicesMeeting a wider range of needs

Secondary processing such as double-sided adhesive tape on polishing pads, specified size cutting, grooving, and slurry holes

is available upon request to meet your application needs.

Size Cutting

We offer polishing pads cut to the desired size and shape. Pads can be cut into many different shapes, including round, square, donut, and fan.

Grooving

The pitch, width, depth, and shape of the grooves can be tailored to your needs.

Slurry Hole Cutting

Slurry hole cutting is also available. Please contact our sales office for more information.

We have established a production system that integrates non-woven fabric manufacturing, resin impregnation, and nap layer formation at our plant.

By carefully managing each process, we are able to flexibly respond to a wide range of technical requirements from our customers.

Artificial Leather Business

Creating fine chemical materials that will continue to brighten our lives into the future.

As fashion, sporting, or lifestyle goods, leather products have become part of our lives and bring color to our days.

Artificial leather—a material made using fiber and polymer technologies—has proved highly popular since its inception. While retaining the natural texture, beauty, and delicate structure of natural leather, artificial leather is available in colors and patterns that are hard to find in natural leather, and also provides new functionalities such as water-repellency and a lighter weight.

Bellace is FILWEL’s flagship artificial leather brand. As we become more aware of the need to preserve the natural environment, we aim to promote the use of Bellace and other artificial leathers as an alternative to natural materials in people’s everyday lives and pursue new areas of need and value for our products.

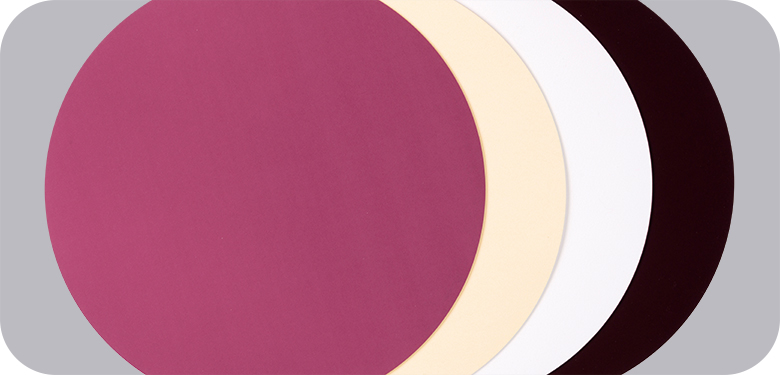

Bellace®Bellace®, our proven and trusted flagship artificial leather brand

A material that showcases the artificial leather technologies developed over many years to replicate the delicate structure of natural leather.

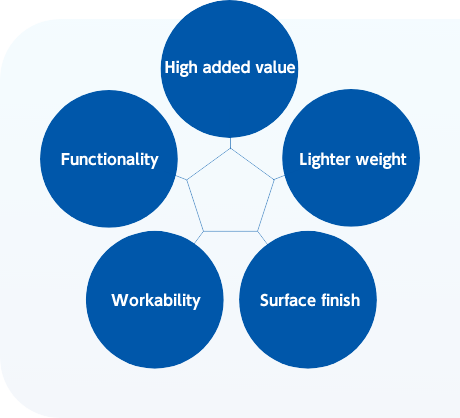

With its excellent suppleness and lightness, the Bellace series continues to evolve towards higher functionality and higher added value.

Bellbio®

This material has a solid texture like real leather, but is scratch-resistant, lightweight, and fully waterproof, making it ideal for school bags.

Patora®

Uses a special polyurethane resin as a binder for the non-woven fabric. Patora has more nuanced texture and its character and performance are showcased in products such as belts, watch bands, and attaché cases.

Belesa®

Like with Patora, a special polyurethane resin is used as a binder for the non-woven fabric, but Belesa is thinner, making it a popular lining material for cases.